K Values For Pipe Fittings Pdf

The k values of fittings in laminar flow can go into the hundreds or even thousands and one measly little 2 0 isn t going to bother anybody.

K values for pipe fittings pdf. Pipe size inches sch. Schedule 40 head loss per 100 values are usually used for other wall thicknesses and standard iron pipe size o d s. The environmental application factors given in table 1 2 are not to be confused with the design factor df used in previous editions of the ppi handbook and in older standards. 15 year old pipe the friction values for old pipe are based on williams and hazen coeffi cient of c 100.

Chapter 6 design of pe piping systems 158 1 1 1 2 where pr pressure rating psi hds hydrostatic design stress psi table 1 1 a f environmental application factor table 1 2 note. Select the appropriate k value for such and select d and f for schedule 40 pipe from the table below where k is the pipe diameter in feet. Once an equivalent length of pipe is determined it is added to the actual length of pipe to determine total losses. Values for 3 inch and larger sizes are for cast iron pipe.

The resistance coefficient method or k method or excess head method allows the user to describe the pressure loss through an elbow or a fitting by a dimensionless number k this dimensionless number k can be incorporated into the darcy weisbach equation in a very similar way to the equivalent length method. 2 2 l 1 h k v g. Friction loss through fittings friction loss through fittings is expressed in equivalent feet of the same pipe size and schedule for the system flow rate. Bends elbows tees and other fittings valves open or partially closed.

The values of k have been experimentally determined and provided in figure 10 2 and table 10 1. Energy lost is because of turbulence. Assume a 6 angle valve for schedule 40 pipe size. A viscous effects are neglected.

Smaller sizes refer to steel pipe. 3 4 4 effect of the fitting roughness. K loss factor has no units dimensionless sudden enlargement. Amount of turbulence depends on the differences in pipe diameters.

40 d feet f pipe size inches. The main causes of the pressure losses in pipe fittings are the changes in direction and cross sectional area. Determine the pressure at point 1 if. The equivalent length of pipe is representative of the frictional loss within a fitting or valve that would produce the same loss due to friction equivalent length is determined by the following equation.

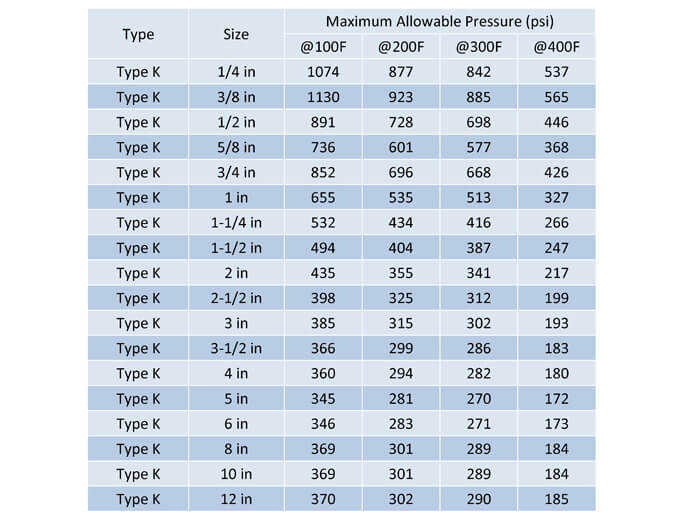

For existing older type installations these higher values are generally used for estimating friction losses. Diameter copper pipe a drawn tubing at a rate of q 0 8 lt s and exits through a faucet of diameter 1 3 cm as shown in figure. Resistance coefficient method k method. Item 1 2 3 4 1 1 1 4 1 1 2 2 2 1 2 3468 10 12 14 16 18 20 24.